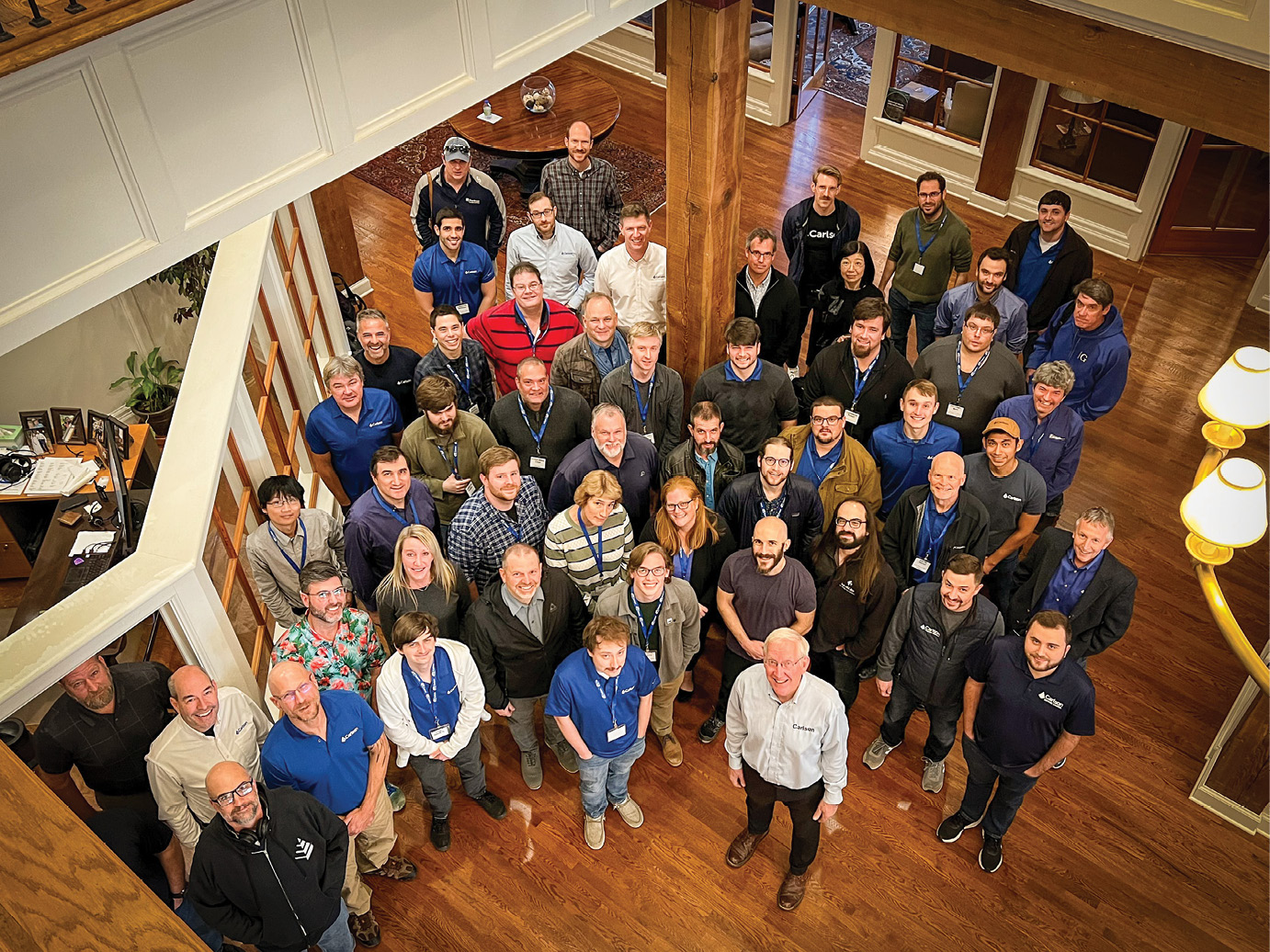

Part of the Carlson Team from around the world recently gathered at the Maysville, KY Corporate Headquarters.

Carlson Software Headquarters are located in Maysville, Kentucky on the Ohio River. The park in the foreground, at the entrance to town, was designed and built by Carlson for the public and made use of many software tools in the product line including survey stakeout and machine control.

Daniel Boone, shown here, was not only a founder of the City of Limestone (later renamed Maysville) but also was a practicing land surveyor in the local area from 1783 to 1785. The first fort in Limestone was built on the location of this park.

Part one of this interview with Bruce Carlson covered the early days, when he was just getting started in software and included stories of Bruce going to extraordinary lengths to win new business or make a first sale. Here in the second half of the interview, Bruce talks about scaling up Carlson Software and its distribution to compete vigorously in a consolidating market dominated by the so-called “Big Three” companies of Hexagon, Trimble and Topcon. The discussion highlights new hardware, software innovations and Carlson’s long record of top-rated service. The following, in Bruce Carlson’s own words, are the secrets to Carlson Software’s success:

People Power

In software and even in hardware, a single person working hard and applying a little genius can make a huge impact, still, even today. Software is like good writing—it is creative and if well-designed, weaves a story that users will enjoy. Corporations do not create best-selling novels. In the same way, you cannot always throw money at software and get results—it comes down to rare individuals, like star authors and athletes, who make it happen. Even laser technology, a hardware element, consists of inexpensive components made to work by applying creative genius to component integration. In our business, one inspired person can change the world. Carlson finds, retains, and rewards such high-performing individuals. The perfect example is Leonid Entov, PhD, our head of Programming, who among other things single-handedly produced polygon “cutting” and sub-zone detection logic similar to core technologies in ESRI and other GIS solutions. This is critical, for example, in “cutting” watershed boundaries against soil types and land covers to precisely calculate runoff.

Carlson Software has instrument “drivers” for many GNSS and total stations on the market, but leads with its own branded GNSS and robotic total stations. Lonny Jones, shown above, is running the Carlson Quarryman scanner used in mining applications.

Competing

Carlson has achieved parity with all the major companies on core measurement technologies. We have in place the software algorithms and the wide range of application software, all designed in a highly appealing interface. Our RTK GNSS technology is world class and will only get better. We have the core laser technology. We have image processing for mapping from photos. We handle pointclouds and mass data sets and are closing in on market-leading feature extraction. Our Machine Control Division has solutions for every imaginable type of heavy equipment. And we have even added gaming technology, STEM video games introducing young people to engineering and to the Carlson interface. We are ready to compete at the highest level and engage in further productization through in-house manufacturing and partnerships.

The Hydrology Video Game is a perfect tool not just for STEM education but can also be used by companies for employee training and to test skills of job applicants. Although sites are currently pre-packaged, the program will soon accept any LandXML2 file containing land covers for precise runoff analysis and design.

STEM Education is a priority from local school districts all the way up to Congressional Committees on U.S. competitiveness in technology. The Hydrology Video Game teaches how to think and design like a practicing engineer, but wtih fun visual effects.

Both Precision 3D Hydrology (P3D) and the Hydrology Video Game work in a true 3D environment with visual display of ponding water and gutter spread. This helps identify locations for inlets and possible issues with DTMs.

Distribution

Carlson worked very hard over the last 10 years to find special individuals who could help us start up a highly reliable, mutually supportive distribution system. We searched for high-integrity, non-aligned individuals who could become “Carlson Centric Dealers”. It took several years to establish our first 3, and they should be mentioned by name: Jennifer DiBona of “That CAD Girl”, Dan Woodruff of “Carlson Preferred Solutions” and Michael Gassman of “Carlson Equipment and Software”. Credit goes to Scott Griffin, Director of Sales, who implemented my dream of a “Centric” distribution, where at least 80% of product sales were Carlson products. We now have 35 Carlson Centric Dealers worldwide, many of them adopting the Carlson branding in their name. Virtually all our established Centric Dealers who joined us after relationships with other firms have reported rewards and revenues like never before. The Carlson Centric Dealer initiative has created a virtuous cycle of success and has built an ecosystem that includes what may be the largest trained internal sales force and trained dealer distribution team operating in the U.S. serving our industry. The Carlson Sales Staff and “Centric” Distribution Team is a true force in the market and appeals to our business and supply chain partners who wish to tap into Carlson and sell through our growing network. We are particularly appreciative of our relationship with Hexagon and Hemisphere in this regard.

The Carlson Machine Control products will track precisely to the bucket teeth on loaders and excavators. Solutions for a wide range of heavy equipment have been developed over the past 25 years, with more emphasis now on integrated solutions at the manufacturer level.

Landfills (shown above) and mines, as fixed sites, are well suited to Command and Control software operating in the Cloud. Carlson Command provides site monitoring and machine efficiency reporting, which applies equally to the “portable” construction site.

Service

Back when it published, P.O.B. Magazine did an annual survey of its readers. On the question of service, Carlson Software scored highest, by far, in every annual report we are aware of. This is who we are. We have always had direct answering of phones and have passed questions to our large Technical Support Team headed by Lon Watson. Service is free and universally appreciated, but special priority is given to customers on maintenance, who also receive product updates. Service isn’t only about answering questions—we learn from our customers, who have a direct impact on all our software and hardware products.

Carlson PDGrade is shown here placing a new pile for solar panels. Pile Driving utilizes GNSS as well as IMUs to guide the process. Close cooperation with machine manufacturers is necessary for optimal automation.

Carlson has been in Machine Control since 1997. The Division is growing rapidly with a particular emphasis on drill navigation, pile driving (ie. for solar panels) and landfills. Dealers are now being hand-picked for a renewed focus on construction and blade control.

Work to be Done

We have a problem in our marketplace. There are too many “silos”. There are too many proprietary file formats that cannot be deciphered, file formats for digital terrain models (DTMs), file formats for alignments and for GNSS localizations. This leads to problems in data exchange and causes many in the construction industry to re-create DTMs from scratch, often using only PDF files, which are in effect “paper plans”, nothing more than a pretty picture. The self-interest of the large firms in keeping files proprietary forces too much duplication and burdens the surveying, construction, and CAD/mapping industries with extra work. It adds cost to every city, county, state and federal project, and our competitors should reconsider closed, proprietary formats. By contrast, EVERY file produced by Carlson Software is open, or if binary, our file formats are published or available on request. We are willing to share the format of everything our software produces, in sharp contrast to virtually all our CAD and hardware competitors.

This current state of affairs forces Carlson to invest in file deciphering. This shifts the cost of prying open our market onto Carlson and a few others. This is one reason we push for adoption of the LandXML2 format for data exchange, which we lead on and develop. This format covers everything from survey raw data to DTMs, cross sections and horizontal and vertical alignments. We are a big believer in the “intelligent TIN”, DTM files that include attributes such as land cover, depths of materials, date of construction, etc. With intelligent TINs, 3D views “come alive” with textured surfaces for concrete, asphalt, forest areas, grassy lawns, or buildings of various types.

New Paradigm is Needed

Accurate Terrain Models based on the Intelligent TIN Files in LandXML2 format (or equivalent) is the way forward. To fully automate design and construction, there is a desperate need to create fully accurate TIN models that include details such as precise curb and gutters, driveway curb cuts, even land covers and surface conditions including the handicap ramp mats as well as concrete and asphaltic roads. When the industry moves to accurate TINs, then contractors no longer must “make things work”. If the accurate TINs are in LandXML2 format, they can be shared across all CAD and machine control products. If the LandXML2 files go so far as to include land cover (“intelligent TINs”) plus local regulations and locally available construction items (i.e., inlet and headwall types), even advanced hydrology calculations can be conducted with accurate pricing, as in our new game, Hydrology Engineer. The Hydrology Engineer game will soon be open to LandXML2 files submitted by design firms leading to crowdsourcing of design. When extended to subdivision and site design, a world of “gamers” can find best, lowest cost solutions thereby improving design on a worldwide scale. A “spark of genius” anywhere in the world could lead to a better design. This is a “game-changer” indeed.

It’s Up to Us

That’s our motto. We cannot and should not rely on others to step up. Many have stock market and other imperatives to consider. So, It’s Up to Us!”

Angus Stocking is a former licensed land surveyor who has been writing about infrastructure since 2002.