Delft, October 9th, 2020. Atmos UAV, the fast-growing Dutch drone manufacturer that develops high-end VTOL fixed-wing drones for surveying and mapping applications, proudly introduces a series of upgrades in Marlyn’s flight planning and control software, MarLynk. The new features will be available for new and existing users.

Amongst a long list of improvements, the two features which according to the team will have the biggest impact on user experience with Marlyn, are (1) the enhanced corridor mapping to plan more easily and maximize the coverage of long-assets mapping and (2) the new intelligent checklist which is focused on the man-machine interface (MMI) by integrating automated system checks that result in completing the pre-flight procedure faster without compromising on safety.

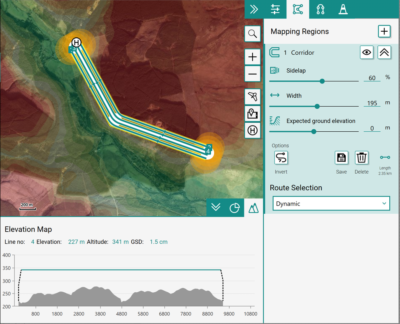

Introducing Enhanced Corridor Mapping for maximized coverage

Atmos’ engineers went to the drawing board and challenged the status quo of how corridor mapping is being planned and executed by almost, if not all, fixed-wing drones out there. They came to the conclusion that the standard way of planning and executing corridor missions was simply outdated and that needed to be improved. So far, every drone needed a new approach for every segment created, which is simply not efficient and furthermore very time consuming.

Taking into account the flight characteristics of Marlyn, the team found a way to make the drone simply continue the corridor without the need to re-approach for every line, without compromise data quality! Resulting in more energy left for mapping and therefore, maximized coverage for each flight (see figure 1).

Figure 2: A screenshot of the intelligent checklist where it has automatically detected and verified the specifics of the camera.

Releasing the intelligent checklist, improving the man-machine interface to increase efficiency and safety of operations

Something that professionals across different industries such as construction, mining, forestry and agriculture have in common is that they are all interacting on a daily basis with machines from all sizes, from GPS sticks up to excavators as big as a house.

This interaction or man-machine interfacing becomes even more important with flying machinery as it is crucial to verify that the system is functioning as expected, before taking off. To that end, Atmos put much effort in developing and verifying an intelligent checklist which guides the operator through the procedure to verify that all the subsystems are functioning correctly to guarantee a safe flight (see Figure 2).

“As we are interacting so frequently with machines it is crucial that working with one is as easy as possible. Our team has managed to bring the operator and Marlyn closer together by focusing on the Man-Machine-Interface to increase the efficiency of Marlyn users.” commented Ruud Knoops, Head of After-sales at Atmos UAV. He continues: “We could not have done this without our distributors, customers, and beta-testing users, that have been providing us with so much positive and constructive feedback on how we can improve Marlyn and the processes around it”

“This has been the biggest motivation for our engineering team to work around the clock for the last 6 weeks to make this happen, and it is just simply amazing to see the entire list of improvements they achieved in this short time span” commented René Worms, Commercial Director at Atmos UAV. “We look forward to show our new features at the Intergeo Digital 2020 and discuss them with professional users around the world”.

About Atmos UAV B.V.

Founded in 2013, Atmos UAV is a Delft (NL) based company specialised in the design and production of high-end aerial surveying and data collection drones that enable professionals to effortlessly gather geospatial data from the sky, enabling them to make more informed decisions. The flagship drone model Marlyn has a worldwide unique design that combines the high performance of a conventional fixed-wing aircraft with the flexibility of helicopters. With their patented technology the company targets mapping, construction, mining, agriculture, environmental and related applications.

Locations: Molengraaffsingel 12-14, 2629 JD Delft, The Netherlands

Phone: +31 (0) 15 744 0321

Email: sales@atmosuav.com