Firm uses advanced LiDAR technique to scan difficult-to-reach commercial ceilings

Surveyors who’ve been in the business a while are probably familiar with this scenario: A client comes to you with a task that calls for using LiDAR to scan the details of a ceiling. Perhaps this is ahead of a redesign or the installation of new equipment on the roof, and the ceiling in question is that of a large commercial facility—60,000-100,000 square feet.

Unfortunately, it’s also covered by ceiling tiles. That means the tiles have to be removed before your scanner can do its work. In our case, the facility was an existing grocery store, which is to say a business that’s operational every single day and can’t afford downtime. The store wanted to add solar panels on the roof and needed to know more about the structure underneath.

In these types of jobs, the information you’re looking for covers everything from what pipes, wiring and climate control systems are up there, to what types of beams support the structure. We also want to know what the supporting structure is made of and how its components are configured. This gives us the structural analysis we’re looking for, so the client can decide whether the roof will support more weight.

Often at this point—upon learning that all the tiles have to be removed—the client says, “never mind” and walks away. That is, if we haven’t walked away first. It’s a two-day job and calls for the client hiring another subcontractor to do the tile removal. Or the LiDAR scanner can be dropped altogether and the client reverts to the traditional method: sending someone with a ladder and measuring tape. Not exactly the most accurate and safest of techniques.

The timing of this request happened to be about two years ago, right in the middle of the pandemic. We didn’t want to turn down work. So, we got creative with our LiDAR scanner and came up with a new way to do this, all in one night.

The conventional way of scanning a ceiling would be to mobilize on the ground level (once the ceiling tiles are removed) and move horizontally to multiple vantage points to capture the entire ceiling.

Obviously, we couldn’t do that with the tiles still in place, so we rented a scissor lift and put one of our surveyors in it, while another surveyor remained on the ground for safety and support. The surveyor judges which tile to pop open, opens it, and then goes into the opening with the scanner mounted on a tripod to begin scanning.

The first few times we did it there was some trial and error, but we were fortunate to have some of our best surveyors on the job. The task calls for skilled professionals who take a continually active mental approach to their work, who can think on their feet and adapt in real time—problem-solvers. These are your people you might call “surveyors at heart.” (It also helps to have people who are not afraid of heights.)

One important detail to keep in mind is that by moving the scanner around in this way, you’re upsetting the reference points that the scanner would normally rely on to position itself and merge the information it generates. If it’s at ground level as it scans the whole ceiling, and then you move it to a different spot, it can calculate this new position on its own based on the ceiling features it had previously scanned. But moving it from one opened tile to another, like we were doing in this new way, made it impossible for the scanner to do that without a little extra help.

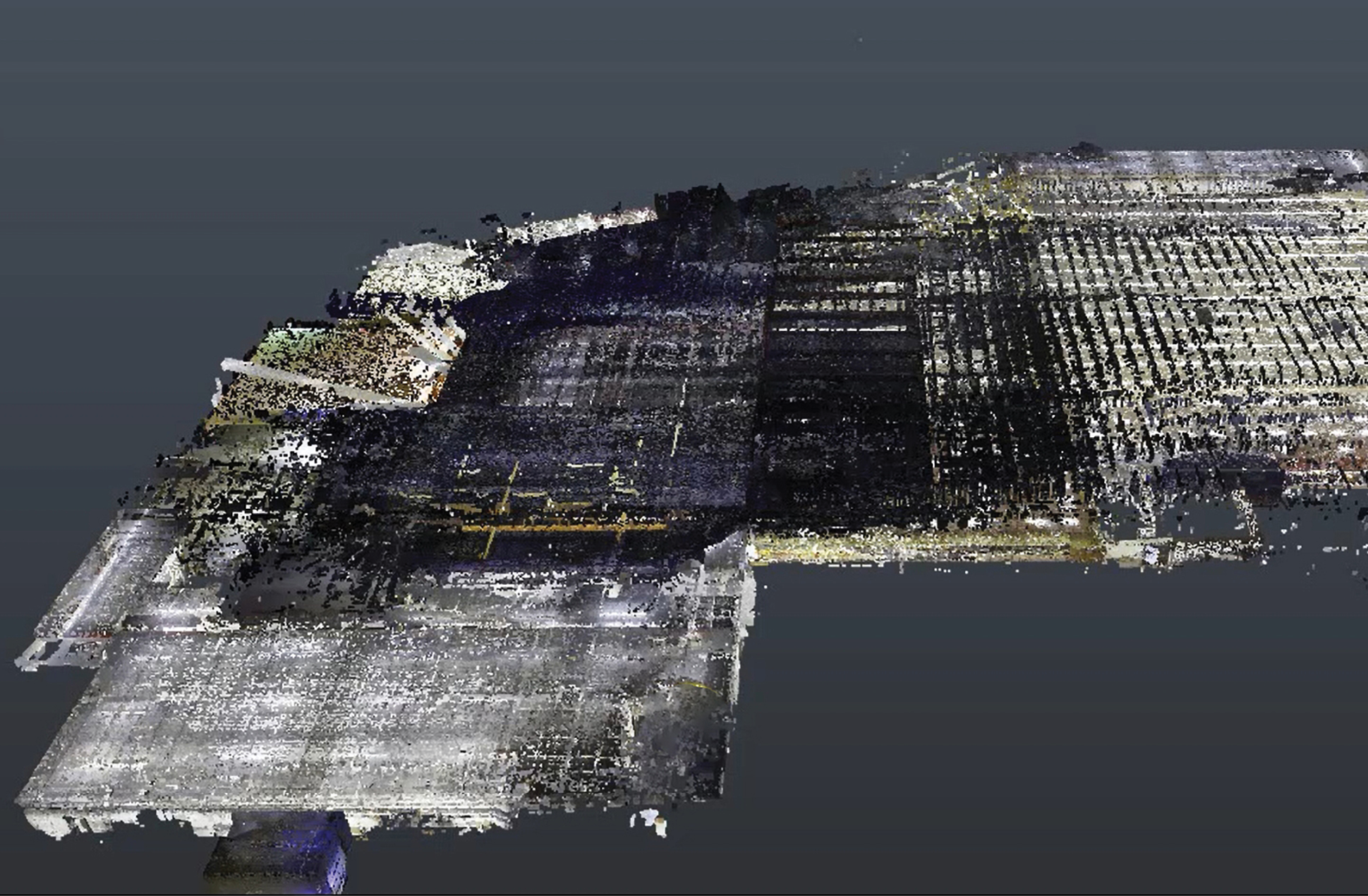

We learned that by having our surveyor move the scanner vertically in the cavity in which the surveyor was operating, the scanner would eventually begin to recognize features it had previously scanned. We can then map these pieces horizontally to develop the entire landscape of the structure and generate the complete final imagery.

By our third store, we were on a roll! We nailed down our processes and were able to quickly assess which tiles to pop so we wouldn’t have to disturb as many of them. The key is being able to identify what’s in the way of the scanner and how to work around that in the most efficient manner possible. Can we go another 10 feet or 30 feet away and pop open another tile and see between the two? If we can, that determines the distance. If something is in the way, then we open more tiles in between. This is why a surveyor who is experienced with a LiDAR scanner is so important.

We ended up doing 15 grocery stores for that client, who now has another 15 lined up for us to scan. Thirteen of the original 15 are up and operational with their new solar installations. Two didn’t pass the structural test. That is a success in itself given that it let the client know two of the projects weren’t worth pursuing, and money wasn’t wasted trying.

Soon after we got started on those sites, another client came to us, again on behalf of a grocery store. This time, it wasn’t about adding weight to the roof, but redesigning the store. The client was Cuhaci Peterson,™ a nationally recognized architecture and engineering firm specializing in end-to-end commercial design solutions and headquartered in Central Florida. We recently completed our first project using this LiDAR ceiling scanning technique, and more are in the works.

“We’ve been partnering with grocery retailers of all sizes for more than 40 years and being able to utilize this system on one of our grocery projects is the type of product innovation we’re excited to be part of,” said Cuhaci Peterson Project Manager Zach Yarnall. “It’s more efficient, specific and truly is a win-win for our clients. We’re thrilled about what’s to come.”

We found this technique to be both elegant and accurate: elegant because of its simplicity and the speed with which it can be done, and accurate because of the precision and richness of the data generated. Results from the old ladder-and-measuring tape method tend to be riddled with errors and missing data with several inches or even feet missing at points, necessitating revisits and further measurements

No one likes turning down business. With this new method under our belt, we can say YES more often to our clients on complex scanning jobs we didn’t, or couldn’t, take on in the past. Applying LiDAR in this way allows us to capture 100% of a project that we wouldn’t otherwise have. And the clients are happy because they are no longer faced the unwieldy prospect of removing every single tile of their ceiling and potentially disrupting their operations and damaging the tiles and other equipment.

This experience should match nicely with Bowman’s acquisition of Spatial Acuity, completed in November of 2022. The Texas-based company provides high-definition scanning and 3D modeling services—including 3D building information modeling (BIM). BIMs are a next-generation, incredibly high resolution, and interactive versions of traditional 3D models.

The resources this partnership brings will allow us to take our LiDAR technique well beyond grocery stores. It could be useful for any type of building or scenario that calls for the removal of ceiling tiles to scan the structure underneath. Office buildings, hospitals and schools come to mind. By solving this challenge, we have successfully opened up a new, and repeatable, service line for our clients. ◾

Marc Olmeda, principal at Bowman, is a professional land surveyor with more than 20 years of experience in the field. Continuing education, self-growth, and the ability to think outside the box allows him to problem solve with unique approaches and the ability to set standards of excellence.