Bryn A. Fosburgh, Senior Vice President, shares the evolution of Trimble and technology culminating with the view of today and tomorrow.

Nearly twenty-five years ago I had a Trimble 4000 on my back and a compact L1/L2 antenna with a ground plane on a prism pole. I was staking a huge earthmoving job in Columbus, Ohio that we landed because we promised the contractor speedy delivery with a new technology called RTK On The Fly. We had one base running two rovers and burned through the bundles of lath like it was nobody’s business. Sometime during the project I fell downward through the muddy clay into the bottom a wet detention basin. As I lay stuck in the gluey silt like a turtle on his back, the party chief assured me that one day they’ll just hook the GPS to the graders and we’ll be looking for a new line of work. A quarter of a century later, I stood on a promontory east of Las Vegas, Nevada overlooking the dust and reality of autonomous machines sculpting a digital terrain model across the ambiguous desert landscape. Trimble Dimensions 2018 was a living demonstration of the automated field to finish workflow and the modern surveyor was center stage in every act of the show.

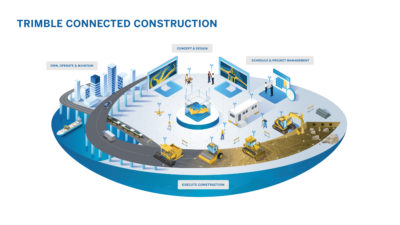

The automated project encompasses every phase of planning, construction and life cycle management. Paving occurs near the end of construction but pavement management extends throughout the life of the infrastructure.

History has proven the fearful detractors of digital construction flat out wrong! So rest easy, we are not being replaced by machines. In fact, it’s proving to be quite the contrary. An automated digital workflow not only requires the skill and competence unique to land surveyors, it actually creates new opportunities to expand core services as a collaborating member of the design, construction, and project management teams. Trimble has spent decades creating, refining, and perfecting every tool needed to develop existing plots of ground into the healthy smart cities that are emerging on the near horizon. Trimble Business Center (TBC) is the hub of the workflow and provides collaborators with a synonymous workshop.

Attendees synergize among the tools and technologies that have redefined the way the world plans, builds, and manages infrastructure.

The surveyor is emerging as the terrain manager for the duration of the projects and beyond. Case in point and according to Arizona DOT regarding the current $1.9 Billion South Mountain Freeway Project “…the private developer will design, build and maintain the freeway for 30 years, including fixes small and large.” I read that as three decades of data acquisition, construction staking, asset management, monitoring, and measurement work for the surveyor. Here’s our opportunity to flourish as a profession and attract young bright minds.

Before there’s even a highway project, there’s a “public need” to be sorted out. A highway concept starts off with a surveyor capturing existing open source digital mapping from a cloud based source. Using Quantm Alignment Software in TBC the design team integrates that source mapping with design standards, terrain, geology, hydrology, environmental impact zones, property ownership, and cost information to deliver a range of alignment alternatives that can be analyzed with project owners and stakeholders. The result is efficient planning and faster delivery of an acceptable route proposal to the community. Right out of the box the surveyor really leverages value on the team with the ability to research boundary and ownership data. Property acquisition is a huge chunk of the budget and often dictates the viability of alternative alignments.

The TSC7 enhances project connectivity through the guidance of underground utilities, vertical construction, site work, and highway construction.

With the preferred route established, the consultant employs Sketchup software to render visualizations and flyovers featuring traffic interchanges and bridge mockups for public presentations. Considering the speed of Trimble’s TX scanner and MX Mobile Mapping System, the surveyor can offer the design team some really appealing renderings for public consumption. Cost effective backdrops of existing features can be combined with conceptual design elements for presentations. This is a biggie for me because nice renderings can ease public uncertainty and buy support for unpopular initiatives. Once again the surveyor is a value adding team member.

So the project has been embraced by the public and the surveyor comes to bat for the design team by preparing detailed material quantity takeoffs quickly and accurately with TBC software. Rapid extraction of cross-section information from PDF vector files quickly reveals specific locations and quantities of materials. The Road Takeoff Tools Pack Plus expands the power to quickly form a model and call out the locations and quantities of materials throughout the entire corridor. This is another value adding task on the project surveyor’s “to do” list. That brings us our 2018 Trimble Dimensions rope stretching “moment of clarity”. Trimble has cleverly captured the role of the modern surveyor within the Road Takeoff Tools Pack Plus brochure. Ironically the construction industry is lagging in its terminology and currently identifies the needs of “Site Data Managers” and “GPS Managers.” Algebraically speaking I see those as like terms and sum it up in the equation “Site Data Manager” + “GPS Manager”= The Modern Surveyor.

Power users share lessons and ideas right on conference floor with Trimble’s nuts n’ bolts folks. Cutting edge practices flourish among a full host of active equipment poised for users to illustrate successful concepts. The focus is on the user and as shown the TSC7 and SX10 actively supported the experience.

Okay, the contracts are in place and the design build project kicks off. Now the heavy lifting begins and TBC is the heart of the project. The entire project team organically gathers together in TBC with all of the tools, knowledge, muscle, and brain power to resolve every challenge between now and the day your grandkids will safely toodle down this highway in their autonomous vehicles. Landscape Architects, Hydrologists, Geologists, Architects, Civil Engineers, Structural Engineers, General Contractors, Earthmovers, Utility Contractors, Pavers, Material Suppliers, Haulers, DOTs, Local Agencies, FHWA, and project stakeholders collaborate and communicate in one common profession language called TBC. Oh, did I forget to mention the site data manager and GPS manager in that embarrassingly overburdensome list? My bad, the surveyor does that stuff now, right? Refer to our previous equation because at this point in history it carries a larger impact to our profession than the law of cosines.

Trimble TSC7 and SX10.

Design build is of course just what it says. The design team works in tandem with the build team and the whole machine works through solutions on the fly. Models are prepared and shared with the project team via TBC’s cloud-based Connect feature. Harnessing the power of the cloud, TBC implements two winning lottery tickets in the design build process. Prolog notifies, delivers, and tracks RFI’s across the cloud. All players are informed of the problem, the cause, the solution, any statistics, and the costs. The surveyor eases the team’s burden by providing real-time measurements of the conflict and field cross check measurements of solutions. My money says this is a big game changer in controlling costs and maintaining the stability of the project capital. Let’s face it, the construction industry yielded a “build it and back charge” business model in the anxiety of the last boom. I see Prolog as a great equalizer to the old fashioned mayhem and disorderly project management styles of yesteryear. Vico Office is a similar application focused in the architectural realm. Again, the power is the team’s ability to see the project moving around them. Cross-checking models in the virtual realm allows updates to be published before the issue becomes a change order. Takeoffs and schedules are adjusted prior to expending materials, resources and labor. Vico and Prolog are the tools that enable humans to harness the productivity of automation. These platforms are redefining our performance measures as well as introducing the notion of obsolescence toward the unpredictable risks traditionally assumed by the construction financing folks. Tekla Structures is a structural model-sharing platform and a very close runner up to Vico. All of these tools serve to iron out any wrinkles before the hammers start swinging. The cause is to mitigate spiraling costs caused by weak planning and poor management habits lingering from the last building boom.

Remember the carpenter’s phrase “measure twice, cut once”? Well, the design build process is “measure always, and build it right”. Anybody that has passed through a Kiewit Transportation project knows that it looks like a drive-by survey equipment show. R10 rovers on the ground, SX10 scanning total stations, S- and C-Series total stations—you name it and it’s there. And every GNSS rover or total station is tethered to a TSC controller. Regardless of the brand, the dynamics of “design build” are measurement data, connectivity, and collaboration. That construction zone you drive through is the forward face of Trimble Business Center. Behind the scene TBC is the manufacturing facility, warehouse, and distribution center of all interactive site data.

Remember the carpenter’s phrase “measure twice, cut once”? Well, the design build process is “measure always, and build it right”. Anybody that has passed through a Kiewit Transportation project knows that it looks like a drive-by survey equipment show. R10 rovers on the ground, SX10 scanning total stations, S- and C-Series total stations—you name it and it’s there. And every GNSS rover or total station is tethered to a TSC controller. Regardless of the brand, the dynamics of “design build” are measurement data, connectivity, and collaboration. That construction zone you drive through is the forward face of Trimble Business Center. Behind the scene TBC is the manufacturing facility, warehouse, and distribution center of all interactive site data.

So back to that hill east of Vegas. Trimble set up a full blown construction site in conjunction with Dimensions 2018. The dust was rolling off of every brand and color of machine in yet another industry encompassing list created by Trimble. Caterpillar, Case Construction, John Deere, Bobcat, Doosan, Epiroc, Gomaco, Hitachi, Hyundai, Kobelco, Liebherr, Link-Belt, Power Curbers, Power Pavers, Vermeer, Volvo, and Wirtgen were all churning and burning under the synchronicity of Trimble’s digital command. I’m reading between the lines here and although nobody said so, it appears Trimble might just have the secret sauce that all of the heavy equipment manufacturers are craving. Innovation attracts a crowd and sure enough all of the big players were kicking up dust on Trimble’s hill. It’s apparent that a huge reality has been achieved in the world of automated contracting. Homogenizing every piece of iron is fundamental to projects like the Arizona 202 South Mountain Loop. Partnering contractors are starving for the cohesion offered by Trimble and are embracing the technologies that orchestrate the entire lifecycle of infrastructure.

“…I stood on a promontory east of Las Vegas, Nevada overlooking the dust and reality of autonomous machines sculpting a digital terrain model across the ambiguous desert landscape.”

There’s more to these super contractor collaborations than just moving dirt in concert with a paving schedule. Design/build/maintain is a long-term trend in saving public transportation funds. Civil Integrated Management (CIM) is commonly defined as the technology-enabled collection, organization, managed accessibility, and the use of accurate data and information throughout the life cycle of a transportation asset. The Federal Highway Administration and state DOT’s are embracing this concept as the highway sibling of BIM (building information management). Trimble’s Novapoint software is the CIM solution for civil engineers to effectively coordinate all aspects of modern roads, railways, tunnels, bridges, signage, water and sewer. Trimble Novapoint Infrastructure Design Suite (IDS) is the cross-feature platform connecting the new infrastructure in a single model.

One of many highlights of Trimble Dimensions 2018 was the captivating series of sincerely inspiring presentations provided on opening day. Relevant content was presented in an enjoyably refreshing delivery that engaged the wall to wall crowd.

Dimensions really is a power conference. Many innovations were promoted that are similar in execution but not really at the forefront of the surveyor’s mind on a project. Nestled in the Fleet Management vertical is the H2250 Haul Truck Monitor that eliminates tally sheets with a focus on safe and productive material movement as well as providing accurate load counting. H2550’s counterpart LOADRITE X2350 Payload System falls under the Civil Engineering and Construction market. LOADRITE is an excavator mounted material management tool that assists with accurate weight distribution and load counting. Automated load count data, volume calculations, and as-built surface data all add up to accurate and indisputable pay requests. The surveyor is well poised to perform this analysis for the design build team.

A pair of positioning tools featured at Dimensions caught my attention as well. CenterPoint RTX is an extremely robust satellite-based real-time correction service supplementing those places that do not have the urban luxuries of connectivity or broadcast local real-time network solutions. Using corrections delivered via L-band communications satellites or wireless IP connections, CenterPoint RTX is capable of producing 2cm horizontal and 5cm vertical accuracy. Places like the African Continent, the Australian Outback, and the remote parts of Central and South America come to mind as prime CenterPoint RTX markets. However, many rural places in the USA lack the connectivity or network solutions as well. CenterPoint RTX statistics begin to look very attractive to those of us engaged in rural and remote mapping of features like watershed drainage basins, mineral pits, and severely undulating terrain. A very appealing feature of Trimble RTX technology is Trimble xFill which provides the ability to continue real-time work if the RTK or RTN datalink drops out. This is a lifesaver to all of us working on the fringes of connectivity or in the rugged canyons that notoriously choke connectivity. Let’s disrupt the norm for a moment and admit we don’t drive or park our cars any better than 2cm. However, I’m willing to hedge a bet on Trimble RTX technology to become a mainstay in the transportation market. We are rapidly approaching the reality of autonomous vehicles on our roads. RTX technology helps pave the way for Advanced Driver-Assisted Systems (ADAS) via Trimble’s global RTX network, capable of transmitting correction streams via L-band, satellite delivery. Parallel parking, vehicle buffering, lane guidance, and who knows, maybe even navigation safety controls through highway construction zones are likely applications for RTX solutions. In fact, Trimble RTX is being used on the road today, providing lane-level positioning as part of assisted-driving systems that offer hands-free driving capability.

The Trimble Alloy GNSS Reference Receiver is an impressive “behind the scenes” piece of positioning hardware. Most surveyors never really think about a Continuous Operating Reference Station (CORS) or Real-Time Network (RTN) base receiver specs, they just connect and go. Anybody in network support knows that the receiver is usually crammed in some nook and buried along a spaghetti of cables. Built in Wi-Fi control eliminates the headache of accessing the otherwise friendly control panel in the dark recesses of an IT server closet. Alloy represents the latest technology and is well suited for static functions including monitoring and CORS. Here’s a real bonus. Trimble RTX is built in; that means wherever you are in the world Alloy will receive GNSS corrections via L-Band satellite or IP/cellular. These delivery options provide opportunities in places where corrections have never been available. Alloy is the latest generation of leading-edge technology and promises robust performance with all constellations over the foreseeable and coming years.

There was no shortage of technology, ideas, training, and of course surveyors at Dimensions 2018. Rope stretchers from all around the globe gather at Dimensions and shape the future of our profession. I was surrounded by the friendly vibe of my colleagues sharing their experiences as if we were all knuckleheads yucking it up on the same crew. Trimble understands our challenges and continually integrates intuitive solutions with user feedback to produce the tools we want and need. So what happened on Trimble’s hill in the desert east of Vegas in 2018? A fully automated construction site and infrastructure management system was deployed, operated, and adjourned in the real world, in real time, and for the whole world to see. Trimble Dimensions 2018 was a gathering of industry’s brightest minds with the most advanced digital platforms and machines in a live interactive venue. Kind of like the Chicago World’s Fair meets a technological Burning Man Festival. The next Dimensions is slated to be in Nashville in 2020.