In 2004, I had the rare opportunity to step outside the traditional boundaries of land surveying and contribute to one of the most unique projects of my career: the recreation of Stonehenge on the campus of the University of Texas Permian Basin in Odessa, Texas. This project was not only an exercise in precision surveying and creative design, but also in collaboration with artists, historians, and engineers to bring an ancient marvel to life in the Permian Basin.

The Vision

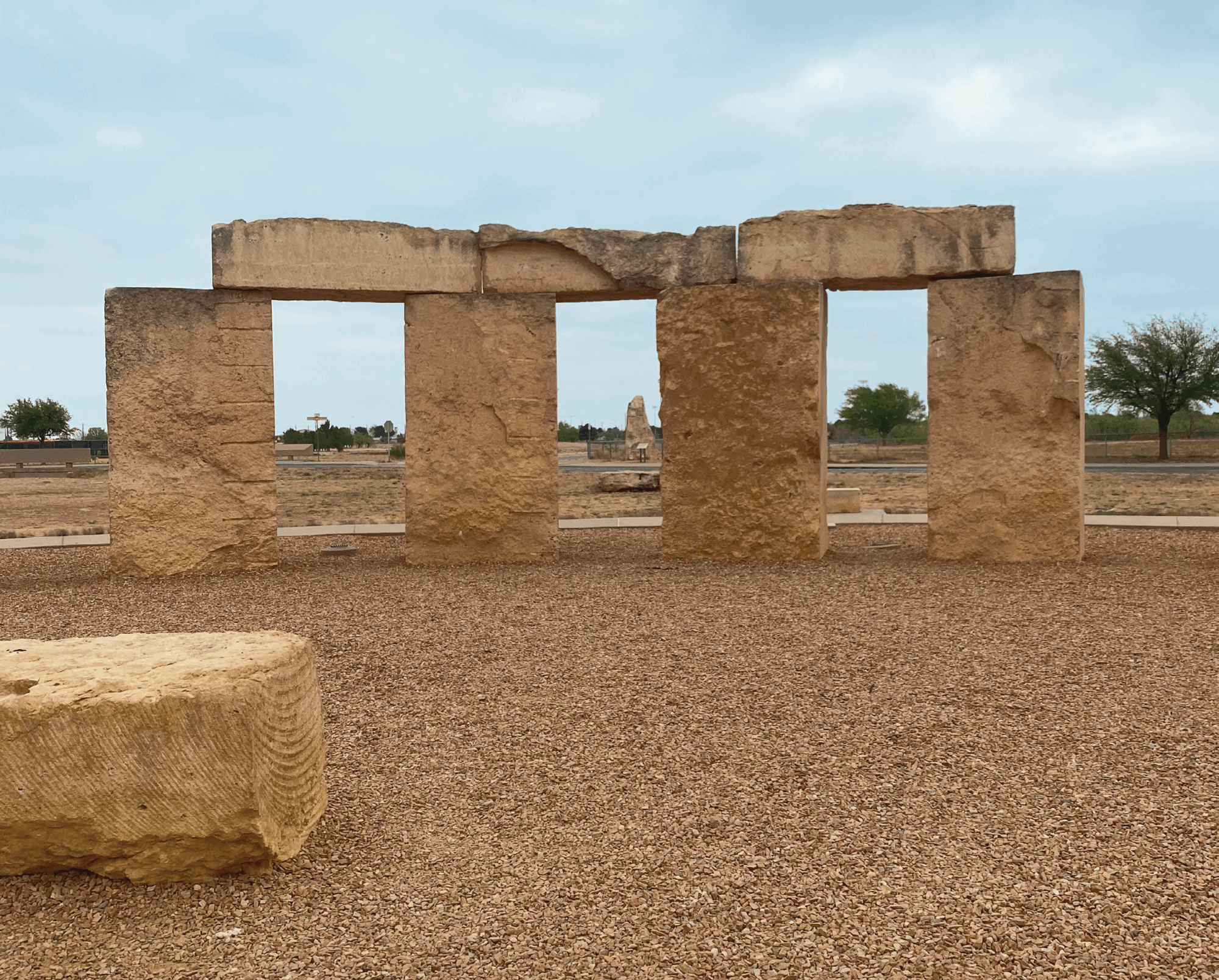

The idea was sparked by a group of local philanthropists and professors who envisioned a full-scale interpretation of Stonehenge that could serve as an educational and cultural landmark. The goal was not to replicate the stone-for-stone ruins, but to create a layout that mirrored the proportions and astronomical alignment of the original monument in Wiltshire, England, while using local limestone slabs sourced from a quarry near Garden City, Texas.

Surveying the Site

The first step was to evaluate the proposed site on the UTPB campus—a flat, open space just off the main loop. We conducted a topographic survey of the area to determine optimal placement, accounting for utilities, drainage, and future campus development. We established a tight control network using GPS and total station equipment to ensure millimeter-level accuracy across the roughly 100-foot diameter layout.

The Odessa Stonehenge is identical in area to the original on Salisbury Plain, England (below), though it is slightly shorter. Burrell and his team were able to match the original stones’ positions relative to their annual solar and lunar alignments. A compass rose marks the center.

With the plane established, the next challenge was translating the original Stonehenge geometry—specifically the concentric circles and horseshoe pattern—into the Texas site. I relied on archaeological diagrams and research materials to derive the layout dimensions, azimuthal orientations, and spacing of each monolith. Every point was calculated in CAD, then staked in the field to mark the exact footprint of each stone’s base.

Translating the Ancient Sky to Texas

One of the most fascinating parts of the project was aligning the UTPB Stonehenge to celestial events—just as the original builders did over 4,000 years ago. Our goal was to ensure that the Heel Stone on the eastern edge of the monument aligned with the summer solstice sunrise, just as it does at the original site in England.

To do this, I first determined the solar azimuth for the summer solstice sunrise at the geographic coordinates of Odessa, Texas (approximately 102.3°W longitude). Using astronomical ephemeris data, I calculated that the sun rises at an azimuth of approximately 61.9° on June 21 at our latitude. I then rotated the entire CAD layout of the stone circle so that the central axis—from the center of the inner horseshoe to the Heel Stone—pointed precisely along this bearing.

However, a campus light pole was located directly in the path of the sunrise view. It would have obstructed the sun on the morning of the solstice, compromising the visual effect. After coordination with university officials and facilities staff, the pole was relocated outside of the sunrise corridor to preserve the alignment.

A Compass Rose brass disk was installed flush with the ground at the exact center of the monument. This disk serves as a fixed geographic reference, orienting all visitors to true north. The disk is engraved with degree markings, allowing observers to stand at the center and look toward the Heel Stone, directly along the 61.9° azimuth that marks the summer solstice sunrise.

To position the stones accurately, we studied satellite and aerial imagery of the original Stonehenge. Using Google Earth and historic overlays, we identified which of the 30 outer sarsen stones were missing or had fallen and determined their original upright or fallen orientations. This research guided the placement of our own 30 outer stones. Since 360° divided by 30 yields 12°, each stone center was placed on a 12° radial interval, forming a perfect ring. Stones with intact lentils at the original site guided the placement and height of their counterparts at UTPB.

We also recreated other important features, including the Slaughter Stone and the Midway Stone—the latter placed along the central axis between the Heel Stone and the center disk, again based on its proportional distance from aerial reference material. The inner horseshoe of five trilithon stones was digitally outlined from satellite imagery and positioned in our layout using CAD software, maintaining the proportions and curvature seen in the surviving monument.

Lunar alignments were considered as well. The original Stonehenge incorporates four “station stones” thought to be aligned with the moon’s extreme rise and set points. We honored this tradition by placing four corner stones at the outer boundary corresponding with major lunar standstill azimuths.

Design Challenges

Unlike the ancient builders, we had modern surveying tools at our disposal — but we also had to account for practical constraints. The limestone slabs, each weighing between 12,000 and 20,000 pounds, were all different shapes and sizes. I worked closely with the crane operators and stone fabricators to develop a plan for setting each stone vertically and aligning them with the intended solar and lunar alignments.

Another layer of complexity came from the irregularities in the quarried limestone. Since no two stones were perfectly uniform, I had to modify the CAD model after field measurements of the individual slabs were taken. We customized the layout in real-time, so the visual proportions and alignments remained true to the intended design.

Construction Coordination

This was a highly coordinated effort involving engineers, surveyors, crane crews, welders, and university staff. I was on site daily to ensure that staked points were followed precisely, and that each stone was placed on its intended alignment. Even small errors could have compromised the intended sight lines and symbolic layout, so precision was paramount.

Engineering the Site Experience

Beyond the surveying and alignment, we were also responsible for producing the engineering plans for the entire site. That included the design of the sidewalk layout that encircles the stone arrangement, providing accessibility and encouraging thoughtful movement around the monument.

Each stone slab foundation was individually detailed in the plans to support the weight and shape of the unique limestone monolith it would hold. Because the stones varied in size and base profile, no two slab designs were exactly alike. Some required additional footing depth or bearing area to safely support the weight, especially for the taller vertical stones near the center of the arrangement.

Lighting was another critical component. We designed a low-profile illumination plan that highlights the stones from below, creating dramatic shadows while avoiding light spill that could interfere with the monument’s naturalistic setting or its intended celestial alignments. At night, this creates a powerful interplay of light and shadow and emphasizes the monument’s mass and geometry.

The engineering design was supervised by John Landgraf and Murray Crutcher, who provided oversight and guidance throughout the process. Their experience and leadership ensured that the structural and civil design components were both practical and aligned with the project’s vision. The three of us were all listed on the bronze plaque mounted at the site’s entrance.

Legacy

The UTPB Stonehenge replica has since become a fixture of the campus — a place for students to study, locals to visit, and schoolchildren to explore. It also stands as a testament to what land surveying can accomplish when paired with historical research, artistic vision, and engineering expertise.

Designing and surveying this structure was more than a job — it was a rare blend of science, symbolism, and engineering. From aligning ancient solar paths to relocating modern infrastructure, from staking monoliths to engineering their foundations, it challenged every skill I had as a land surveyor and civil designer. To this day, it remains one of the projects I’m most proud of — not just for how it turned out, but for what it represents: the power of geometry, intention, and precision to connect us to something timeless.

Aaron Burrell is a registered professional land surveyor with more than 30 years of experience in boundary, construction, topographic, and geodetic surveying across the state of Texas. He currently serves as a Senior Survey Project Manager at Lamb-Star Engineering, based in the firm’s San Antonio office, where he leads survey operations for transportation, infrastructure, and land development projects.