As a surveyor in Alaska there are tales of travails in the field which appear in many journals. The biggest was the boundary survey between Canada and the U.S. while claim disputes during the gold rush in the early 1900’s continues today long after the paystreak has paid out. Just south of the arctic circle 160 miles in Fairbanks, Alaska there is a new gold rush. But this one involves busloads of summer tourists. They come in huge cruise ships to disperse throughout the interior to experience the lore that was Alaska in golden days of yore.

As a surveyor in Alaska there are tales of travails in the field which appear in many journals. The biggest was the boundary survey between Canada and the U.S. while claim disputes during the gold rush in the early 1900’s continues today long after the paystreak has paid out. Just south of the arctic circle 160 miles in Fairbanks, Alaska there is a new gold rush. But this one involves busloads of summer tourists. They come in huge cruise ships to disperse throughout the interior to experience the lore that was Alaska in golden days of yore.

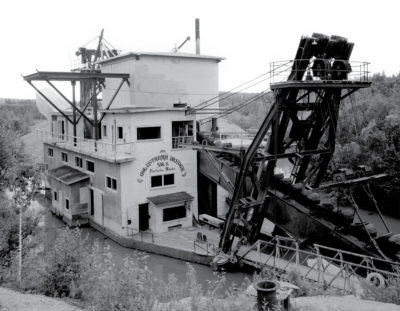

One very lucrative tourist venue is an abandoned gold dredge in Fairbanks. It was one of eight huge floating stacker dredges which ate up gold bearing rock left behind when the early drift mines had been sold by the early miners. They were no longer productive for small mining operators with pans, picks, shovels, and sluice boxes. These small independent operations were replaced by heavily financed mining exploration corporations from the lower 48 States.

Goldstream Dredge No. 8 was operated by the Fairbanks Exploration Company (FE), a subsidiary of the United States Smelting, Refining & Mining (USSR&M) out of Boston, Massachusetts from 1928 to 1959. It is located on the Old Steese Highway between Fairbanks and Fox in the central part of Alaska. Starting in the 1920s, water was brought to the area through the 90-mile (145 km) Davidson Ditch for placer gold mining. Goldstream Dredge No. 8 cut a 4.5-mile (7.2 km) track and produced 7.5 million ounces of gold.

The dredge was named an Historic Mechanical Engineering Landmark by the American Society of Mechanical Engineers in 1986. In 1984, it was listed as a historic district on the National Register of Historic Places. It has been open to the public during summer months for tours of the dredge, mess hall dining at the old bunkhouse, small conferences, and gold panning for a fee.

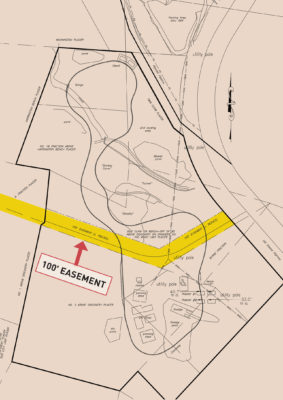

Since being converted to a tourist site in the 1970’s it has been owned by three different operators. Recently it has been embroiled in a lawsuit over a 100’ wide access easement between the original developer, John Reeves now operating as Fairbanks Gold, LLC and a local tour operator named Godspeed Properties, LLC. Godspeed operates a fleet of three large replica stern wheel paddle boats on the two main rivers in Fairbanks. That company is named after their first 25 passenger river excursion boat, Godspeed which started the local family tour business in the 1960’s.

I first became involved in the kerfuffle in 2012 when I was a platting officer at the Fairbanks North Star Borough (FNSB). It was my job to process a preliminary plat application by Reeves to subdivide a US Mineral Survey (USMS) adjacent to the Gold Dredge

No. 8 venue, now owned by Godspeed.

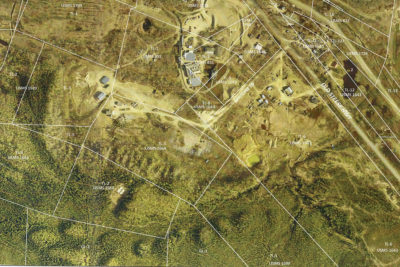

Catwalk photo indicating location in oblique 1987 aerial (shown lower left below) used to scale first draft exhibit of conveyors.

Godspeed was upgrading the operation at Gold Dredge No. 8 by building a replica of a narrow-gauge railroad that served the goldfields from 1904 to 1926. The train rides provided a narrative to paying visitors of what gold mining was like during the dredge operations. Reeves was proposing to use a 100’ wide access and utility easement granted by the FE company when they owned all the placer claims in the area. In order to meet the FNSB road standards for public access, Reeves proposed to build a minor collector with 60’ of ROW within the 100’ access easement. While the subdivision application was being processed Godspeed laid over a mile-long loop of narrow-gauge track twice across Reeves proposed access road to his subdivision to be named Calder Gulch Tracts.

Godspeed appealed the proposed plat asserting that Reeves access would disrupt their tourist train operations. Reeves had been approved by the Alaska Dept. of Environmental Conservation (ADEC) to use Calder Gulch Tracts to bury uncontaminated building construction debris with the mine tailings deposited by the dredge over 50 years prior. The access was proposed to be named Landfill Road to reflect the purpose of Reeves construction and land development business.

Godspeed appealed the proposed plat asserting that Reeves access would disrupt their tourist train operations. Reeves had been approved by the Alaska Dept. of Environmental Conservation (ADEC) to use Calder Gulch Tracts to bury uncontaminated building construction debris with the mine tailings deposited by the dredge over 50 years prior. The access was proposed to be named Landfill Road to reflect the purpose of Reeves construction and land development business.

Original survey plat of Gold Dredge #8 camp for Godspeed, LLC showing narrow gauge tourist train tracks crossing 100’ access easement proposed to be dedicated with 60’ ROW for Landfill Road.

The issue was exacerbated by Reeves proposed road crossing Godspeed’s tourist train tracks if it became a public road under the FNSB management authority. The proposed Calder Gulch Tracts was granted preliminary approval on March 21, 2012 but stalled for final plat approval until the crossing issue could be settled. Godspeed and Reeves then began a long string of motions, injunctions, and counter claims that finally went to the Alaska Supreme Court that resulted in a decision regarding the easement in 2013.

The primary assertion by Godspeed for not allowing Land Fill Road as access was that it had been blocked by a rock processing plant for the statutory period to have been vacated by prescription. When Reeves owned Gold Dredge No. 8, he had given permission to a local miner, Harold Ellingson in the early 1980’s to operate an experimental gravel extraction mill on an adjoining USMS. Ellingson’s plant had an additional process designed to remove gold from the old tailings that were being made into gravel for road construction projects in Fairbanks. It was in operation from 1987 to 2002 and was jokingly called either a gravel plant with gold as a byproduct or a gold plant that generated gravel as a byproduct; both end products generated substantial revenue.

The supreme court ruled that a portion of the 100’ access easement had been obstructed to make dedicating a 60’ wide public road not possible. On remand it had to be determined that Ellingson’s gold plant had extinguished a major portion of the easement by prescription. This may have included the four conveyor arms which discharged gravel and if they could be considered a permanent structural component of the plant.

The attorney for Godspeed hired two different survey firms to determine how far the conveyors projected into the 100’ easement. However, the plant was dismantled after 2002 leaving only the footprint of the structure visible in aerial photos. These two surveyors could only make renderings of the plant when it was shown or absent on aerial photos from 1984 to 2002. The issue was compounded for any corroborating testimony by Ellingson because he had died several years prior and his widow did not have a firm recollection of the gravel plant construction. Lacking any physical evidence of the plant in 2012 along with insufficient renderings of the purported easement in relation to the plant, Godspeed hired me in 2018 to take a stab at it.

I reviewed the six prior court drawings that were made using hard copy portions of the original 9” x 9” aerial imagery upon which they had attempted to scale the location of the plant within the easement. No ground surveys were conducted with only crude scaling of the easement in relation to buildings visible in the aerials. The exhibits were not accepted as sufficient evidence to determine how much of the 100’ easement had been blocked.

Gold plant control cab with hopper feed conveyor for raw gravel and one of four adjacent discharge conveyors. Photos courtesy of Alice Ellingson

My mission was to help define the encroachment adequately for a definitive resolution to how much of the easement was obstructed by the plant during its operation. My first task was to recover as many corners as possible of the six USMS which comprised the Gold Dredge facilities or abutters. Then I searched for any evidence onsite that may indicate the location of the plant.

If the plant had been built on a permanent concrete foundation it was removed by the time the preliminary plat of Calder Gulch Tracts was submitted. Lacking this primary evidence, I did find the 6” and 36” diameter steel pilings that had supported one end of a 100’ long steel pedestrian walkway for tourists to view the gold plant in operation from a platform 21 feet above the ground. But the elevated walkway had been removed when the plant was disassembled. I hired a licensed professional engineer/surveyor/geologist who used his Javad GPS units to tie down the pilings and nine of the recovered survey corners for the USMS tracts. This included power poles, buildings and the train tracks crossing the entrance to the Gold Dredge tourist facilities.

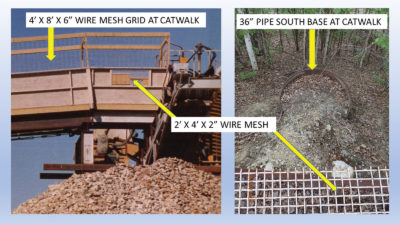

Initially since the first remand hearing was scheduled for September 2018, I had only been able to use some terrestrial and oblique aerials that were taken of the gold plant in operation beginning in 1987. These were oblique, uncontrolled, unrectified amateur photos taken by tourists or employees with very little information except for rough scaling of the catwalk and conveyors. I discovered the catwalk had been outfitted with steel mesh lattice work to act as a 4’ high protective barrier on both sides to keep visitors from either falling off the catwalk or getting pelted with gravel while it operated for the tourists.

The Ellingson’s had several hours of video documenting the gold plant for investors in 1987. This was also to show the University of Alaska Fairbanks School of Mines which had been studying this new design that delivered two valuable products, gold and gravel. They also had two professional photographs taken with a large format camera for their office display. These high-resolution images showed the extensive steel mesh grids that lined the catwalk, along with various platforms on the plant to access the machinery operating 24-7 during the long daylight of Alaska summertime.

I recovered two of the steel lattices where the catwalk base was still located. They measured at 4’ x 8’ with a 6” mesh (used as reinforcement in concrete slabs) and the smaller 2’ x 4’ with a 2” mesh (used as screens for sifting the gavel). Using these as basically grid paper on the photos and videos I was able to determine the rough dimensions of the plant, catwalk, and conveyors.

Since the evidentiary hearing was coming up in September, I made a draft pretrial exhibit with these derived dimensions of the plant footprint and conveyor arms. I noted on the draft that these were informational only as we were awaiting drawings from the Anchorage firm of Quantum Spatial, Inc., owners of the aerial images from 1984 to 2002.

After filing those, the trial was set for late October 2018. Quantum Spatial had rendered an AutoCAD drawing from four aerials taken in 1993, 1996, 1997 and 1999 when the plant was visible. I inserted their digitized points into my now completed drawings with accuracy and detail that I felt comfortable with for going to trial.

Based on these better data provided by Quantum Spatial, I was able to determine the horizontal and vertical dimensions of the plant, conveyor arms and catwalk attached to it. The anchor points of the catwalk along with several buildings and power poles visible in the photos had been tied down with my GPS field survey points. Based on this more accurate data, the plant dimensions were refined. I determined one conveyor arm only left 57’ of the easement unobstructed while the plant footprint was 35’ by 45’ on the ground.

However, this did not prove if the four conveyor arms were permanently affixed to the plant base because all but one remained in the same position due south while the other three appeared to pivot with a swing axis from the plant roughly 20 degrees each way. Godspeed hired two separate mining engineers who argued that even if some of the arms were able to pivot, they were necessary to distribute the gravel piles so a loader could fill up dump trucks. They were integral to the plant as a whole processing unit.

A parallel argument was made that the two conveyors on the huge floating dredge to extract the gold ore for processing had a similar integral function. Without the pivoting front conveyor buckets scooping rock and the rear one discharging spoil piles like some aquatic Pacman, it would simply be a barge mired in its own waste.

After taking nearly six months to decide, the argument did not prevail with the judge’s decision on December 16, 2019. He ruled that Godspeed did not prove with any photos or testimony that the conveyor arms were permanent structural components that reduced the 100’ ROW to less than 60’. Godspeed’s assertion that the easement was too constricted by the conveyors was denied. Reeves could build his subdivision access road within the 60 foot right of way as proposed in 2012.

Another motion was heard at court on June 11, 2020 for Case No. 4FA-12-02133 CI to decide how the road crossing would be accommodated by Godspeed to not conflict with Reeves use as Landfill Road. The longstanding battle between these two titans of the tourist industry is akin to the old Japanese movies of Godzilla versus Rodan. No matter who wins Tokyo still gets trampled in the process after many sequels.

The subsequent judgment and permanent injunction decreed July 3, 2020 in superior court resulted with an order that the two parties must reasonably accommodate mutual use of the easement. They were ordered to make six accommodations for using it jointly. Now the devil will be in the details and more than likely result in claims and counter claims for who got the short end of the agreement. Tokyo may rise from the ashes but the rebuild may take another battle before the train and trucks can safely cross.

Examining in more detail the judge’s ruling on my expert witness testimony and evidence, I will delve further in part two of this article.

Martin Gutoski has been a licensed land surveyor in Alaska since 1988, with more than 30 years as platting officer at the Fairbanks North Star Borough Planning Dept. He holds a master’s degree in anthropology and has been involved in historical archaeology projects since 1994 and forensic survey analysis since retiring in 2014.