In 1976, an explosion in Culver City initially left nine dead and 26 injured. The explosion was caused by excavators striking a gas line, due to an 18-inch error in information about the utility line’s location. Mike Mullen, Herald Examiner Collection/Los Angeles Public Library

On June 16, 1976, the community of Venice Boulevard in Culver City, California, was humming with construction for a street-widening project. But then, with one fatal excavation, gasoline shot up and a wall of fire formed. The howling eruption was the result of a front-end construction material loader striking a high-pressure petroleum line. The deadly cloud, filled with petroleum spewing from the ruptured pipeline, rained down, pouring over 16,000 gallons of low-lead gasoline over businesses, residential properties, and unsuspecting citizens passing by. At first, bystanders and motorists remained fixated on the growing clouds of black smoke in the sky, until moments later when the hot exhaust turned the once bustling, sunny block into a giant hazardous fireball. The disaster took nine lives and left 14 others severely injured in what was later, in reports, reduced to an 18-inch utility location error.

Today, not many surveyors or utility industry professionals know about the Culver City gas line explosion; after all, it was nearly 45 years ago. But from the ashes of the Culver City tragedy came necessary changes in industry best practices for locating utilities, color-coded markings, excavation practices, site inspections, utility coordination, and even One-Call notification programs. Moving forward, Culver City and its industry impact shed light on the path forward for the development of best practices and how surveyors can lead the charge in protecting underground, and thus above-ground, assets.

Flaws Acknowledged: Investigations and Reports

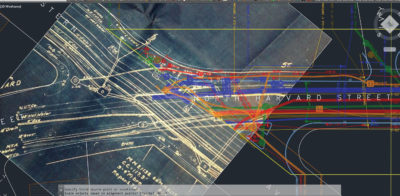

The map above produced by the DGT Associates SUM team superimposes underground data from remote sensing technologies with the original underground blueprint, combining 100 years of history in one place.

In the aftermath of the Culver City explosion, investigators discovered troubling circumstances that contributed to the event. The initial shock turned to outrage at the apparent inadequacies in planning, design, and construction practices, identified as the cause of the accident. The chairman of the National Transportation Safety Board (NTSB), Webster B. Todd Junior stated, “Someone should make damn certain exactly where that pipeline is located. You don’t fool around in a situation like that.” The final investigations and subsequent reports identified several key factors that lead to the event.

First, the project owner and design team failed to locate the exact position of the underground facilities—two high-pressure product lines—and accurately depict their locations on the construction plans. Instead, the owner used contractual language in the project “Standards and Specifications” requiring the winning contractor to work with the underground asset owners to determine the location of underground lines. As stated in the contract, “The contractor shall ascertain the exact location of underground main or trunk lines whose presence is located on the plans or in the special provisions.” While the winning contractor did contact the pipeline operator and other underground asset owners, only a few test holes were performed in the early phase of construction and the nearest survey location of the pipeline was positioned 300 feet from the accident site. Essentially, for months, no one on the project knew the exact location of the high-pressure lines.

A critical aspect of Subsurface Utility Mapping (SUM) is utilizing legacy data as well as new data to maintain the integrity and authenticity of all of the data presented.

Next, while the records indicate the pipeline owner worked with the contractor to communicate the approximate location of the pipeline, the final report also suggests the pipeline owners could have done more to protect the integrity of the pipeline. Little effort was made to monitor the construction site, and no attempt was made to verify the pipeline depth. What was most troubling to the NTSB was no one disputed the fact that the high-risk pipeline was known to be shallow and in conflict with the proposed work. As concluded in the NTSB report, “No attempt was made to verify the pipeline depth at the accident site, even though 700 feet of the pipeline, near the accident site, had previously been lowered because of insufficient depth. Although the line was known to exist, its precise depth and location were not known by the pipeline operator, the construction contractor, the subcontractor, or the Department of Transportation.”

Best Practices Rise from Tragedy

Michael A. Twohig, Director of Subsurface Utility Mapping for DGT Associates, scans for underground utilities on airport grounds using electromagnetic induction (EMI). Many handheld devices now incorporate GPS-connectivity to allow the uploading of the information live into GIS environments.

Following the Culver City explosion, federal and state organizations aimed to better protect civilians and underground assets by establishing what is now known as the Common Ground Alliance (CGA). The CGA eagerly worked on developing methods for every contractor or project owner to notify other stakeholders about their intent to break ground in hopes of sparking consistent and reliable communication about underground asset location. Born out of this idea was One-Call centers.

By 1994, there were 71 individual One-Call centers across the United States. Receiving a staggering 15 million calls per year, it was clear that communication was improving between asset owners. However, all the One-Call centers were operating with different 10-digit numbers. To gain even higher participation, the federal government in 2002 strengthened its support for the One-Call program by requiring the Department of Transportation (DOT) and Federal Communications Commission (FCC) to establish a three-digit, nationwide toll-free number that unified the 71 individual centers. Today, 8-1-1 is the universal “Call before you Dig” number.

While 8-1-1 has helped to establish communication regarding the intent to dig, it has not solved the problem of communicating in real-time on project sites. At sites, project owners often rely on paint marks on the ground—urban hieroglyphics—as an on-site communication method of underground utility locations. But the only true, accurate way for project owners to perform proper risk assessment at a project site—relating to underground utilities—is by implementing an integrated system for locating, mapping, and communicating underground information.

How Surveyors Can Further Improve Subsurface Utility Mapping

New wearable LiDAR technology, like the one seen above by NavVis, allows capturing of the built environment above-ground, including paint mark-outs, so that it can be merged with subsurface information to give a more complete depiction.

Subsurface Utility Engineering (SUE) is the most common approach today to gaining a comprehensive view of underground assets beyond One-Call centers and paint mark-outs. SUE gained the seal of approval from the Federal Highway Administration (FHWA) in 1991, and shortly after, the Purdue study demonstrated its cost-effective nature. The study found that 71 projects observed a total of $4.62 of savings for every $1.00 spent on SUE. This study validated SUE as a valuable technological practice with the ability to reduce costs, as well as increase project safety, and should be used across the industry. With this, the American Society of Civil Engineers (ASCE) National Consensus Standard titled ASCE C-I 38-02, Standard Guidelines for the Collection and Depiction of Existing Subsurface Utility Data. These progressions built on CGA’s work and further solidified a regulated process of breaking ground.

Under these ASCE 38-02 regulations stem four levels of service. Level D consists of locating underground assets by reviewing as-built plans and existing documentation. This method is the most fundamental level of accuracy. At the highest accuracy, Level A uses existing records in combination with noninvasive underground mapping techniques to present the most comprehensive and clear-cut details of what lies belowground. When reflecting on the Culver City tragedy it’s clear to see that test-holing, while a common utility locator practice, left a large margin of error—a margin of error that surveyors, guided by a principle of accuracy, would never allow.

At DGT, we believe that the best method for capturing a complete picture of the underground environment consists of comparing as-built records—a surveyor’s tool—with the findings from what we call Subsurface Utility Mapping (SUM) investigations. Rather than excavating test holes, creating greater risk of exposure and damage, SUM employs sophisticated technology to locate underground assets while leaving them undisturbed. Building on the surveyor’s principle of accuracy, SUM data can be gathered with tools such as electromagnetic utility locating devices (EMI) and ground-penetrating radar (GPR) systems. Today, Ground Penetrating Radar (GPR) can be used to map out and profile a pipeline. You can never perform enough test holes to obtain the level of accuracy you get with SUM technologies.

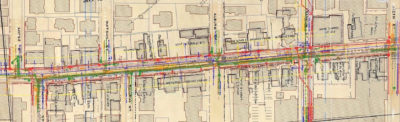

This DGT map shows GIS representation of subsurface utility information in an urban environment. The product of SUM/SIM work is a detailed map that not only locates utilities, but also includes metadata about the type, age, and more to help provide comprehensive information to avoid accidents like Culver City.

SUM, building on SUE, goes beyond just underground data acquisition, focusing equally on data storage and delivery for optimal usage by any stakeholder on a project site. Mapping underground assets adds value, quality, and accountability to the project, therefore creating a safer environment. SUM constructs color-coded 2D and 3D digital files that illustrate the exact location of vital underground utilities. This information is then transformed into Computer Aided Design (CAD), Building Information Modeling (BIM), or GIS models.

Subsurface Information Modeling (SIM) is another technological evolution we see emerging in underground mapping. Established by Michael A. Twohig, DGT’s Director of Subsurface Utility Mapping, SIM blends the best practices of SUM with the model-based processes of BIM. With SIM, utility surveyors utilize terrestrial LiDAR in the design phase of the project and use the data gathered to identify any possible utility conflicts. In the future, industry practitioners will likely use the data gathered from LiDAR to build a “Digital Twin” for Dilapidation Surveys and One Call line markings. This technique will propel the industry to new heights. Additionally, with the use of 3D modeling, project managers will be able to compare site mark-outs in real-time with the data gathered from SUM techniques. Using these practices, projects will avoid costly mistakes, stay on schedule, and create a safer environment for both workers and the public.

Usable—not just Viewable—Data

Using SUM and SIM to gather data and protect assets is pivotal, but the ability to import and store this data in the cloud is also crucial for future use—beyond a single project—in billing, sharing, and querying. Over the past decade, a technological revolution has swept the industry improving information retrieval and data storage.

Recently, new equipment has been designed to include GPS functionality that can be used in tandem with the precise SIM and SUM utility location data. These new excavation tools combine the effectiveness of heavy equipment with the finesse of accurate soil removal that comes from GPS, enabling jobs to be performed quickly and accurately, therefore saving time and money. Another benefit is GPS integration into pipe-locating systems. This technology makes it possible to trace, locate, and map the precise horizontal and vertical location of underground facilities. What’s even more important is the ability to access the metadata from the office, the field, or even in an excavator’s handheld device, and see the precise location of underground systems. With a greater number of people accessing data at their fingertips, successful collaboration and informed decision making is increasing.

Land Surveying in a Modern World

While land surveyors were traditionally focused on assessing the land above ground, their role in underground surveys has increased as technology advances in SUM/SIM practices and cloud-based solutions. Although the CGA, and numerous construction industry organizations, have made strides to mitigate underground infrastructure damage following Culver City, surveyors bring a level of spatial accuracy and expertise to underground infrastructure that is needed to better protect underground assets. By implementing a tactical utility locating and mapping program, led by surveyors, leaders throughout the ASCE community—utility locators, civil engineers, construction managers, GIS technicians, LiDAR specialists and more—will be able to grow the industry together as allies.

In the instance of Culver City, 18 inches was the difference between life and death. Had the team communicated, developed meaningful processes, and utilized equipment, this story of tragedy may have been one of triumph. Today, we must use the techniques, resources, and experts available to us to move the industry forward and prevent repeating the mistakes of those who came before us.

Michael A. Twohig is the Director of Subsurface Utility Mapping at DGT Associates. He is an international subsurface mapping expert with over 35 years of experience in professional utility locating, mapping, damage prevention, and industry safety awareness.

mtwohig@dgtassociates.com