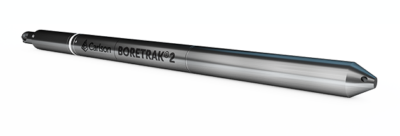

Maysville, Kentucky, U.S.A. (November 2020) — Carlson Software has released the all-new Boretrak®2, borehole deviation measurement system. The Boretrak2 is a simple-to-use, gyro-based system for measuring the deviation of boreholes drilled in underground mines, surface operations, open-pit mines, or quarries.

Carlson’s Boretrak2 was developed as a successor to the well-known Rodded and Cabled Boretrak systems which have had a 35-year product history. The new unit features capabilities of both units and includes a miniature inertial measurement unit (IMU) containing a triaxial accelerometer, magnetometer, and gyro. Prior to deployment, the Boretrak2 is calibrated against a known orientation on a supplied mount – establishing a starting reference azimuth for the gyro. The gyro provides the Boretrak2 with an accurate, live heading which is tracked as the probe is deployed into the borehole. It is not reliant on a magnetic compass or physical rod alignment for orientation.

The unit can be quickly deployed by a single operator using a variety of methods. For downhole deployment, the Boretrak2 can be lowered using a wireline. Uphole and horizontal deployments can be completed using a semi-rigid pushrod system, spooled out from a cable reel. The probe is deployed into a hole at fixed intervals. At each stop, a measurement is recorded in Carlson Scan.

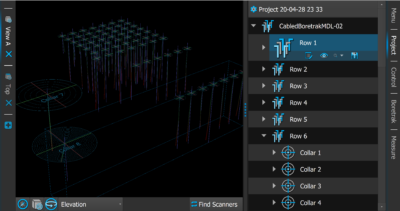

Carlson Scan is the free operating software that runs on an Android device or Windows-powered tablet. It is used to set up projects and design holes, import hole coordinates, and import third-party data to form a background to newly collected data. Carlson Scan is connected to the Boretrak2 by a Bluetooth connection from the operating device which allows for setup and calibration of the unit.

Data recorded by the Boretrak2 is displayed in real-time in an optional 3D graphical mode, 2D schematic mode, or in tabular formats. Reports can be quickly generated, in-the-field, featuring data on each hole with tabular data outlining each reading during deployment. Data can be transferred onto a desktop or laptop version of Carlson Scan for further analysis. Survey data from the Boretrak2 can be exported to other Carlson software packages like Carlson BlastOPS using the DRL format or exported as a DXF or CSV to be used with other third-party CAD and blast design software.

“The Carlson Boretrak2 is the next generation of borehole deviation technology,” says Brad Husack, B.Sc., Support and Special Projects Engineer, Carlson Software. “It is the culmination of over 35 plus years of bore tracking manufacturing and field experience. With the new ability to deploy in every direction and the new intuitive and easy-to-use Android/Windows-based software, Carlson Scan, surface and subsurface operations will benefit greatly.”

The Boretrak2 probe is made of stainless steel and has a waterproof rating of IP68, allowing it to be deployed in extreme and rugged environments. Its 40mm diameter makes it deployable even in small boreholes. Operating temperatures range from -10°C to +60°C.

For more information about the Carlson Boretrak2 or to request an onsite demo, visit carlsonsw.com/product/carlson-boretrak2.

About Carlson

Founded in 1983, Carlson Software Inc. specializes in CAD design software, field data collection, laser measurement, and machine control products for the civil engineering, surveying, GIS, construction, and mining industries worldwide, providing one-source technology solutions for the entire project cycle. Carlson Software is headquartered in Maysville, Ky., U.S.A., with branch offices in Boston, The Netherlands, Brisbane, Australia; Ottawa, Canada; and York, England.