The splendor of Notre Dame Cathedral in Paris is evident before the April 15, 2019, fire, which destroyed the building’s spire and most of its roof, and severely damaged its upper walls.

Historic structures and architectural wonders like the Notre Dame Cathedral in Paris rely on the inventions of their era to stay standing for hundreds and thousands of years. But when natural or human-caused destruction strikes in modern times, it is often geospatial data that holds the most promise of restoring them to their former glory.

As 3D digitizing becomes increasingly valuable in historic restoration, the technical aspects of surveys and point clouds will only grow in importance. Let’s take a closer look at setup, instrumentation, project examples, and the potential benefits of technology advances in 3D laser scanning.

Geospatial data supports revival of world-famous church

With the Notre Dame Cathedral, it was obvious from the moment of the April 15 fire that the structure would be scanned multiple times to accurately determine damages and structural stability and compare with past scans. Point clouds from scans will support the restoration lifecycle, including knowing how to handle the destruction, determining how to support work around existing architecture, and finally, informing decisions on building features, such as replicating what existed before or creating something new.

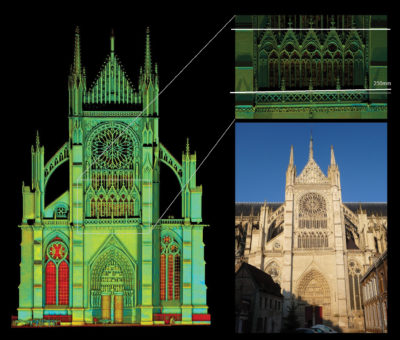

This colored point cloud of the Notre Dame Cathedral in Amiens, France, shows orange triangles that are scanner positions. The ones that appear to be inside the building are actually scanner positions going around it.

Such a project benefits from using surveying companies with specific knowledge of the best workflows for historic preservation and restoration. These specialized companies often have teams that include surveyors, scanning technicians and restoration professionals trained and experienced in historic building materials and techniques.

Instrumentation and setup support restoration

The Notre Dame Cathedral restoration also heightens the sense of urgency for structures and monuments without digital records to get point clouds created before disaster strikes or natural elements erode their splendor.

In these images of Notre Dame Cathedral in Amiens, France, the zoomed portion (top right) of the point cloud of the south facade that includes the Golden Virgin Mary reveals the right side of the balcony is 230 millimeters, or about nine inches, higher than the left. The misalignment may be perceived as a perspective issue from the ground, but scan data confirm it is tilted. Historians dated the stones and found both the right and left of the facade were built first, and when it came time to link them, the architect apparently decided to tilt the balcony to fix the alignment issue.

With this in mind, let’s explore the measurement configuration inside and out, as well as the setup process to create a digital record to aid historic project restoration:

- For scanning small or medium sites, use one or multiple 3D laser scanners, with the setup dependent on size, budget and criticality. Solutions could include a laser scanner and/or a scanning total station, tripods, batteries, and data storage (USB key or SD card). Also recommended, but optional, are black and white targets, spheres and/or survey prisms, as well as an external high-end camera and panoramic head for higher-quality imaging.

- For larger sites, in addition to the above list, black and white targets, spheres and/or survey prisms must be used. If you aren’t using a scanning total station, you will need one total station or one GNSS receiver to establish a control network, which is a skeleton of precise known targets covering the entire site and serving as a reference for all scans to guarantee accuracy over the entire site.

- For continuous monitoring of the critical elements of a building, you will want one, or more often, multiple high-accuracy total stations mounted 24/7 on stable permanent pillars. The setup should also include a number of monitoring prisms to be installed on the critical elements of the building, monitoring controller(s) to provide a continuous connection between the total station(s) and the monitoring control center, and real-time control software.

Techniques reveal more detail

While missing elements, such as roof segments, can’t be measured, fallen or partially destructed elements can be scanned, measured and virtually repositioned to understand what is really missing and provide understanding on how it has been destroyed.

A major consideration in point clouds is photo texture, or the addition of color and texture to a point cloud or mesh to add rich visual detail. To get photo texture, you have two options: an internal camera of 3D laser scanners, selected most often for simplicity and productivity, or an external high-end camera and panoramic head for more expert control and higher-quality imaging.

Historic restoration with 3D models: Three examples

Liuhe Pagoda (China): Reviving a cultural landmark

Liuhe Pagoda (or Six Harmonies Pagoda) in China’s southern Hangzhou, Zhejiang province has a rich cultural tradition dating back to its construction in A.D. 970. In its more than 1,000 years of existence, the 13-story octagonal building made 95% of wood has lived several lives, including destruction by warfare in 1121 and full reconstruction by 1165.

In 2013, the tourist attraction began its fourth major repair and renovation. To preserve the complete, true appearance, the owner entrusted Beijing TiTest Technology Corp. to scan the whole interior and exterior, which occurred over six months to allow for the gradual restoration of missing parts, one by one.

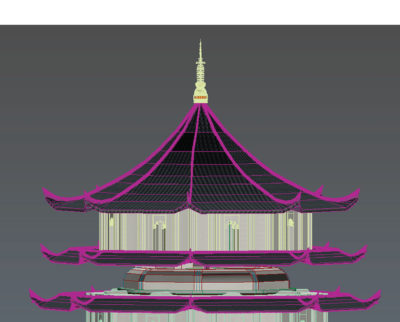

The intricacy of the design of Liuhe Pagoda, at 13 stories high, made it a challenging restoration project.

The workflow included scanning of the original building (3 minutes per station), modeling the original building to find the missing parts (2-3 hours per station), designing the missing parts and testing their assembly (4-6 hours), crafting the missing parts by hand (3-5 days), assembling the missing parts on site (4-5 hours), scanning again for quality assurance (QA) and quality control (QC) (3 minutes per station), processing point clouds for the harshness inspection (QA/QC) (3-5 hours), and lastly, processing a very detailed 3D model for documentation (2-3 days).

Using a compact 3D laser scanner to scan the whole 527 station, the original point cloud data volume reached 363 gigabytes, with 23.03 billion three-dimensional points collected.

The site’s iconic 14-story structure received raw ore delivered by aerial trams from mine entrances in the mountainside above and delivered processed copper to railcars at the base of the structure.

Kennecott Mines National Historic Landmark (Alaska, USA): Restoring a treasure

Located in eastern Alaska, the Kennecott Mines site was declared a U.S. National Historic Landmark in 1987. When the National Park Service (NPS) acquired Kennecott in 1998, it began the lengthy effort to preserve the site and determine which buildings should be stabilized or rehabilitated after nearly 80 years of neglect.

Archaeologists worked to map the site, but by 2018, the NPS started gathering additional data as part of a project to stabilize the upper seven stories of the mill and found the 2000 data lacking in detail and accuracy.

A georeferenced Trimble VISION photo mosaic of the Kennecott mill from the valley floor. Blue lines show GNSS measurements, green are from SX10 traverse and direct reflex data.

To provide the necessary precision, 3D laser scanning was deployed. A team from Frontier Precision Inc. selected the Trimble SX10 scanning total station and the Trimble TX8 laser scanner for the bulk of the work, which tied scans to existing control points and used traverse or resection functions to establish georeferenced 3D positions on each setup point. The team also used Trimble R8 and R10 GNSS receivers to extend control throughout the site. In addition to scanning, the Trimble SX10 used direct reflex (DR) measurements to capture individual points on the building that could identify key features and be compared to the point cloud for quality assurance.

Technicians processed the data using Trimble Business Center (TBC) software to combine the traverse and GNSS results and work on scanning data from the SX10. They used the Trimble RealWorks survey workflow to process TX8 data to project coordinates. Multiple scans were merged quickly, and teams created colorized point clouds for visualization. At the end of the three-day project, technicians delivered a single TBC dataset containing all point clouds, images and survey data.

Church of Saint Simeon Stylites (Syria): Promise of restoration

Initially scanned for preservation, the Church of Saint Simeon Stylites—in the north of Syria—dates to the fifth century and now stands partly destroyed by a Russian rocket attack in 2016. If it becomes possible to restore the church, the scans can be used as a historical record of the structure, making them very valuable.

Since 2003, the site has been the object of digital surveys, according to a paper published in 2011 in the International Archives of the Photogrammetry, Remote Sensing and Spatial Information Sciences.

Shown inside the Landesmuseum in Zürich, the Trimble X7 scanning system, available in early 2020, exemplifies the maturation of 3D laser scanning technology that can support the collection of critical data on historic structures to enable their future restoration after disaster or deterioration.

Authored by M. Kurdy, J-L. Biscop, L. De Luca and M. Florenzano, the paper includes a description of work done at the site by Yves Egels, ENSG, in 2004. Using a Trimble GX scanner, Egels did 36 stations to collect 250 million points all over the cruciform church, which is composed of four basilicas in cross formation around an octagonal drum centered on the famous pillar where Saint Simeon lived and preached for four decades. Registration was done using spheres.

Once the data was gathered and geo-referenced, the whole point cloud was cleaned of unnecessary points, sampled and cut into various elements, following construction logic consistent with reconstruction techniques. The data made it possible to determine how the building was created, including the central octagonal drum. It also enabled the creation of a 3D hypothetical reconstruction.

Simplicity increases accessibility

While manufacturers are working hard to simplify the process of completing a single scan, high-level expertise is still required for a full project like a cathedral. The registration process, or the combining of scans in an accurate way, is one of the remaining barriers to simplifying large projects.

The first developments to provide a pre-registration in the field were only a half-step in the right direction. Extensive processing and validation were still necessary back in the office. To make scanning really simple, a project should be done and final when finishing on site, with no disappointing surprises later. Full registration in the field including refinement to obtain an accurate registration, colorizing, reporting and exporting data in the right file format is a game changer.

Conclusion: Maturity brings benefits

3D laser scanning has come a long way since its beginnings in the late 1980s. Performance, size, weight and productivity have greatly improved, while the total cost of ownership has come down.

Still, compared to other optical measurement instruments like levels, theodolites or total stations, maturity in 3D laser scanning isn’t completely there. Most manufacturers still recommend a yearly calibration to maintain the expected specifications; and standard warranty periods are in general just one year, while all other optical instruments provide two years. With its automatic calibration feature, the recently announced Trimble X7 scanning system is addressing this and other challenges users previously faced with 3D laser scanning technology.

As 3D laser scanning becomes a more mature technology, similar to optical instruments, we will see a much broader use of this fantastic technology. Each new innovation is making it easier and faster to capture precise 3D scanning data to produce high-quality deliverables.

With this growing accessibility, geospatial professionals won’t have to be scanning experts to also benefit from the technology, enabling them to branch into new lines of business, like historic restoration.

Gregory Lepere, marketing director of Optical & Imaging for Trimble Geospatial, has been fascinated with cathedrals since he was a boy growing up in France and has participated in 3D laser scanning of many historic structures during his geospatial career, including Notre Dame in Amiens, his hometown. Email: gregory_lepere@trimble.com