A surveyor captures data during pipeline construction. Rapid measurement and specialized data collection software help ensure compliance with safety and environmental regulations.

Moving product–oil, gas, petroleum–over land via a pipeline is the most economical method of transportation today–but the environmental impact when accidents occur can be catastrophic. This risk has driven an increase in regulations, resulting in more tasks required during pipeline construction. In addition, operators are increasingly mandated to provide more pipeline data, e.g., what is in the ground; precisely where it is located; where it was made; who manufactured it; who welded it; etc. Added to this information are questions about who should record that data; how it should be collected; when it should be collected; and how to easily access the data when it is needed–and data collection can be a cumbersome job. Today, however, there are solutions that exist that can improve the efficiency of collecting this data to ensure the data is accurate and is collected in a timely manner, and won’t impede construction progress. Some solutions are manual, while others incorporate data in electronic form through guided workflows that ensure data integrity and regulatory compliance.

Why More Data?

The largest cause of pipeline failure is material or weld failures. These consist of 36 percent of the causes for pipeline failures (USDOT1). The second leading cause is corrosion at 24 percent, followed by excavation damage at 14 percent. While some of the causes mentioned can’t be completely eliminated, they can be greatly reduced by knowing where the pipeline assets are located in the ground, how the pipe was constructed (e.g., anti-corrosion coating), and where the critical failure points are located.

A surveyor captures location of a pipeline prior to backfilling. Efficient measurement avoids delays during construction.

The age of the pipeline infrastructure will often dictate when new pipelines need to be installed. In the U.S. over 50 percent of the pipelines currently in service were constructed in the 1950s and 1960s. Some of the issues with this infrastructure are lack of data relating to the pipeline’s precise position and where the material was manufactured. In the process of updating the pipeline infrastructure the data needs to be recorded accurately in order to better ensure safety over the life of the pipeline.

Aging pipelines is not often an issue as long as the pipeline operator has sound pipeline integrity management programs. It’s important for the operator to have a good understanding of the infrastructure and the environment in which it has been deployed to ensure a successful integrity management program. However, accurate data capture at the point of installation is even more critical.

To monitor the health of this aging infrastructure, there are many tracking systems in place that collect data regarding pipeline leak and spill failures. This data can be important when analyzing the root cause for failures. If it is determined that a particular type of material from a certain manufacturer was faulty then corrective actions can be taken to eliminate future integrity issues.

The answer should be evident: the importance of getting good data recorded during the pipeline construction process is critical to reducing and preventing future issues. This changes the role of the surveyor during pipeline construction. Why a surveyor? Typically, the surveyor is the last person to “touch” the pipeline assets prior to a dozer covering it in dirt. Because a surveyor’s primary role is to record the accurate position of the underground asset it makes sense to store all the important data that was captured. This helps to ensure the integrity of the data; as well as the pipeline.

Information about welds is stenciled onto the pipe. Photographs capture additional information and can be linked to measured points for comprehensive documentation.

One method reluctantly but necessarily deployed in the past was manually recording data in field books. A surveying crew member would log information manually in a field book. This information consisted of the data stenciled on the pipes and welds, which included location information (typically the horizontal stationing on an alignment) as well as other pertinent data. At close of day these handwritten notes would be entered into a computer to get the appropriate data into the system of record, which of course introduced error possibilities that could ultimately produce bad data.

Surveyors have also been asked to collect more information or to help ensure the pipeline has been constructed in conformance with the parameters defined by regulations, building code, and the operator’s design, to name a few. Some of the key elements needed are:

• Location of welds, bends, valves, connectors.

• Information about the pipeline material (material, coating).

• Other pipe characteristics (length of a joint, outside diameter, inside diameter).

• Depth of cover–how far under the surface is the pipeline?

• Relative position of a joint, valve, and bend to a weld.

• How the pipe was welded, who welded it, and who inspected it.

• How a bend was made–was it prefabricated or was it bent in the field?

As one can see, the amount of data that can be captured is significant and poses challenges to survey crews throughout the industry.

Surveyors must capture essential information along a pipeline. Customized software provides detailed guidance and in-field quality assurance.

Keys to Accurate Data

Ensuring pipeline data is accurately captured has proven to be a big challenge over the years; however, as more data becomes available electronically this problem is reduced significantly. For example, when pipeline materials are delivered to a job a manifest (inventory list) is usually provided. While this was a paper copy in the past, today the data can be available electronically so the risk of inaccuracies is minimized.

Another important factor is to enable all data to be recorded in the same place–not scattered over multiple mediums, i.e., field books, proprietary databases on data collectors, and spreadsheets on computers. This makes many operational tasks easier. Status reports can be generated quicker, and ultimately the final deliverables can be submitted in various file formats to the parties needing the data.

One other key is to ensure that regulations–including legal right-of-ways–and safety concerns are being met. Quite often the pipeline route may be alongside protected wetlands, private property or other areas that must be avoided for legal reasons. Safety risks may potentially arise as well if a portion of the pipeline is installed in the wrong spot–both during construction and years later. So, it is important that a good system offers the surveyor the situational awareness to assist sound decision-making.

One other key is to ensure that regulations–including legal right-of-ways–and safety concerns are being met. Quite often the pipeline route may be alongside protected wetlands, private property or other areas that must be avoided for legal reasons. Safety risks may potentially arise as well if a portion of the pipeline is installed in the wrong spot–both during construction and years later. So, it is important that a good system offers the surveyor the situational awareness to assist sound decision-making.

The processes that a surveyor implements when working on a pipeline construction job may vary from region to region, but are fundamentally implemented in the same way. These processes include:

• Topographical survey prior to any construction.

• Collecting or validating inventory information in the field, or in the pipe yard. (often referred to as the Tally process)

• Recording the relative position of welds and bends to pipe joints.

• Recording the as-built information of the pipeline assets once they are put into the ground, and most importantly, before they are covered with dirt.

Topographical Surveys

“Topos” are the bread-and-butter work of surveyors. It consists of using a survey-grade Global Navigation Satellite System (GNSS) receiver or a total station to measure the corridor where the pipeline is to be installed. Most modern surveying systems support this workflow; however, if it is recorded correctly the data captured here can be very useful throughout a pipeline construction job.

The Tally Process

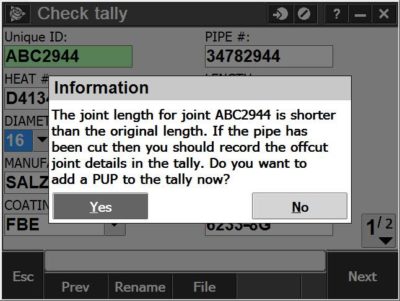

The Tally process is key to ensuring that the inventory going into the ground is what the operator thinks it should be. The surveyor obtains an electronic manifest, typically a Comma Separated Values (CSV) file with all of the data, and must confirm that the data is correct. For example, a pipe joint may be 40 feet long on the manifest, but in reality is only 38 feet. Data validation helps to ensure that the final deliverable is accurate. The tally data should also live throughout the pipeline construction process since it will probably be adjusted. An example of this is when a pipe length needs to be shortened and, what was once a 40-foot pipe is now a 25-foot pipe. Surveyors may not notice this discrepancy until the joints have been welded together so it is important to be able to adjust the data throughout the workflow.

Weld Mapping

Weld Mapping

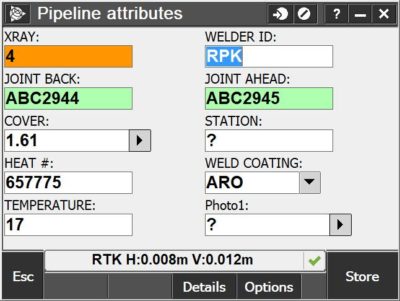

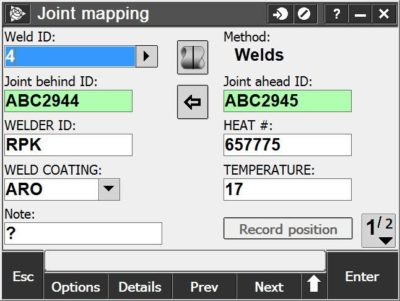

Weld mapping is when things get interesting. The pipeline section may not be in the ground yet so recording the relative position of a weld to the connected joints is relatively easy. This allows the surveyor to associate an upstream and downstream pipe joint with a weld, and if the system works efficiently, the attributes collected or validated during the tally will flow into this process.

As-built Asset Measurement

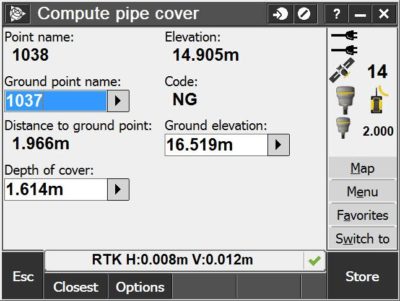

Finally, the as-built measurement of the assets in the ground should tie the recorded data together. The surveyor typically performs this task with a GNSS receiver by obtaining centimeter precision within three dimensions of the asset. In addition to the actual location, the system should record data about the inventory going into the ground, including depth of cover, whether it crosses another pipeline, and other critical information that could impact the operational integrity. Recording where the assets are located is also important because it tells the surveyor if the pipeline is in the wrong place.

Keystone in Midstream

Keystone in Midstream

Keystone Surveying and Mapping, Inc. (KSM) specializes in the Midstream sector of the Oil and Gas industry with the Marcellus and Utica basins, and has used geospatial solutions for this work for years. Initially, they used Trimble® AccessTM software with Trimble R8 GNSS receivers, maintaining a data dictionary and collecting most data in Microsoft Excel spreadsheets.

They recently transitioned to the Trimble Access Pipelines module that incorporates the workflows discussed above as well as other features and utilities to help streamline the surveyor’s role in pipeline construction. “We were still surveying pipelines the old-school way,” said Keith Higgins, PLS and CEO of KSM, “We didn’t choose Trimble Access Pipelines because of field collection issues. We had a data dictionary, we were collecting most of the pipeline data electronically we just didn’t have any connectivity with the data. We made the decision to use Trimble Access Pipelines purely based on the data processing capabilities.”

The results for KSM have been impressive. The turnaround time on deliverables has been greatly reduced, and KSM can provide data for hydro tests, final pipe footages, wall thickness footages, tally reports, number of CAD Welds, number of drain tiles, KMZ files and alignment sheets before the contractor has left the right-of-way. “Using the pipeline module has freed up the time spent going through the reports to clean up errors since many of the errors are caught in the field,” Higgins says.

“Plus, our project managers are happy delivering this data because they know it is 100 percent correct. We still survey these pipelines the “old school way” we just have more firepower behind us,” he said.

Regulations may ebb and flow, but they will never go away. Having access to the spatial information (the where) as well as the asset information (the what) is critical in keeping pipeline infrastructure safe and sustainable for years to come. Ensuring that this data can be captured efficiently and accurately will ultimately reduce costs and keep the pipelines running safely for years to come.

Jason Rossback is a Product Marketing Director for Field Solutions at Trimble, Inc. Jason has been with Trimble for 10 years focusing on delivering solutions for surveying and mapping in many different markets. He and his team spent over a year working with customers in the field to design and develop Trimble Access Pipelines.

1 USDOT: State of the National Pipeline Infrastructure, 2011

Sidebar:

Finding the Right App…

Choosing the right products is important to the success of pipeline construction. Trimble has been a pioneer in building surveying and mapping solutions used in this type of construction. About four years ago Trimble developed a software solution for transmission pipeline construction that complemented its high-precision surveying instruments. The solution, Trimble Access Pipelines, was released three years ago and provides surveyors working on pipeline construction projects with a streamlined data collection application integrating key functions to ease the workload of the surveyor. See More At apps.trimbleaccess.com/Trimble/Pipelines